HGV Series

Located in Austria, MEBREX electric solutions GmbH is always one step ahead.

You can be there when the latest generation of 24V fast charger DC generators comes onto the market.

Whether you want to run your roof-mounted stationary air-conditioning unit, parking heater, cooking infrastructure or electricity supply during engine tick-over time, the MEBREX MEC 1.4 charges the battery twice as fast as the HGV engine, saving the need to buy an extra charger.

The AUTO-START /STOP function increases user convenience. A further substantial feature is that over-discharging is avoided, protecting the HGV battery and increasing its lifespan. Lower installation costs due to easy installation, and potential savings are convincing reasons to make a purchase.

In the add on version, only a plug is required - connect and ready. If you follow an efficient operating strategy with your fleet, and desire to decrease the operating time of your vehicles, there is no way to pass up on the MEBREX MEC 1.4.

Example: A battery with 24V and 120Ah is to be charged, this requires 3h:45min with a 16A charger available on the market. An 11A charger takes 5h:20min. The MEBREX completes the same battery in the fast charging process in 49min20sec time saving 80%! Highest efficiency - highest efficiency

The stationary HGV

The stationary HGV in regard to the environment and costs (Study by Dr. tech. H.J. Schacht)

MEBREX MEC 1.4

-

Nominal voltage 24V DC

Power rating

min. 0,6 KW /4000 Umin

max 1,6 KW / 4500 Umin

max. current 60A

MEBREX HGV – reduction of CO2 Emissions

Summary:

MEBREX electric solutions GmbH deals with the reduction of CO2 emissions in various areas in which fuel is used. One area is the CO2 emissions from trucks and how this could be reduced. It describes when unnecessary fuel consumption occurs on the truck, which relationships were determined. Consequently, it is listed how savings in consumption and thus a reduction in CO2 emissions can be achieved with the MEBREX MEC 1.4. At the end you will find information about the management.

Reduction of CO2 emissions due to lower HGV engine idling.

How can the idling time of HGVs be reduced? Why is there a time when the HGV engine is idling? The reasons as well as the potential for reduction are presented on the following pages.

Engine idling can happen:

-

When the pneumatic brake is pumped following a longer time.

-

While waiting at red traffic lights.

-

In traffic (borders, accidents).

-

During waiting times at terminus, loading stations, closed tunnels with abnormal loads or heavy goods transport.

-

During loading and unloading of swap bodies

-

During charging of the vehicle battery in the rest period stipulated by law to

-

cook (microwave, coffee machine, oven, etc..),

-

to heat,

-

to cool (overnight stops in warm climates with built in roof-mounted air-conditioning units),

-

to watch TV,

-

to charge cellular devices and/or lap-tops.

At MEBREX, we are primarily concerned with the issues in point 6. For this purpose, research by haulers and forwarders, including their logged data (from the HGV manufacturer service point), was carried out and analysed. The following conclusion can be made:

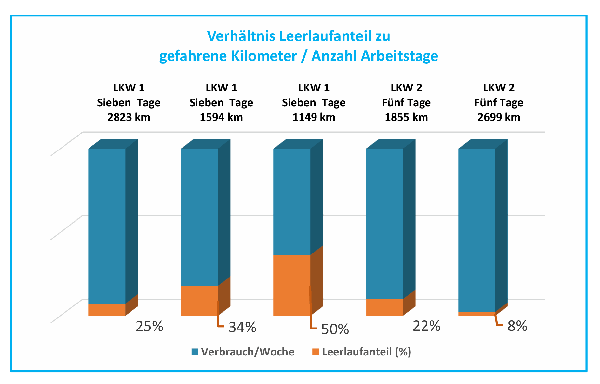

The proportion of kilometres driven to the number of working days to the amount of engine idle time in %.

We could establish that a higher amount of the running engine is idle if

-

the HGV was in operation for seven days, also over the weekend.

-

Or never mind that with seven or five days of work, the kilometres travelled became much less, which drastically increased the break times.

The data shown in fig. 1 is the log-data of from a HGV service station that 2 forwarder HGVs in long-distance transport logged weekly and submitted.

Fig. 1

Reduction of CO2 output through use of the MEC 1.4 from MEBREX electric solutions GmbH.

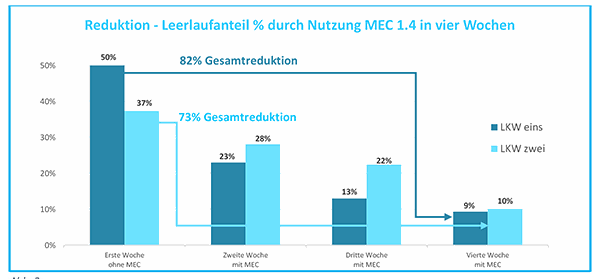

A field test was carried out in order to establish whether using the MEC 1.4 results in a reduction of idle time, as well as a drastic saving in fuel consumption. MEC 1.4s were installed in two different HGVs and tested over a period of weeks.

The "First week without MEC" shown in Fig. 2 represents the initial situation (test week one) of both trucks and their idling percentage. In the first week with the MEC 1.4 (test week two), a reduction of 54% could already be noticed on truck one and 24% on truck two. Due to the growing confidence of the driver in the fully automatic function of the MEC 1.4, there was a reduction of the idling percentage by 82% on truck one and 73% on truck two in three weeks! This is shown in Fig. 2.

Fig .2

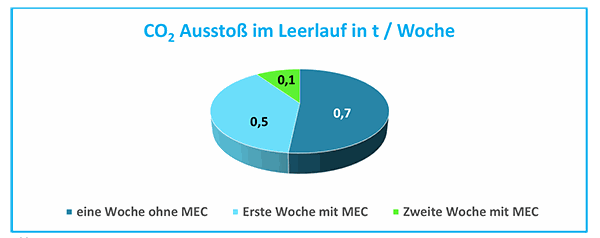

CO2 reduktion:

After only three weeks use of the MEC 1.4, a reduction in CO2 of more than 17.9% could be realised.

Fig .3

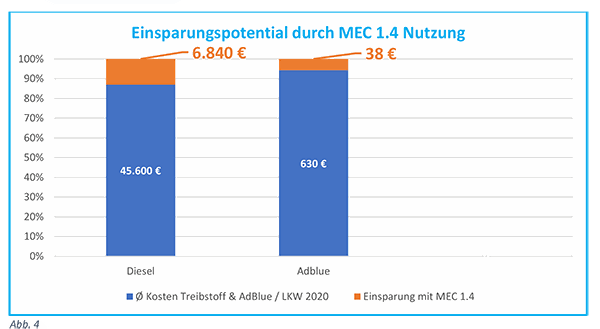

Possible potential savings per year through use of the MEC 1.4

IThe topic of the competitiveness of German carriers compared with competitors in Eastern Europe and the Baltic states has been covered in Springerverlag’s diverse „VerkehrsRundschau“ broadcasts. Potential savings could possibly make German transportation companies more competitive.

Fig. 4 illustrates how much a carrier could saving per year and HGV in fuel costs. The average values to calculate the illustrated data were determined as follows:

-

Total yearly kilometres = Frauenhofer study 2019 “climate balance, costs and the different potential fuel and engine types for cars and HGVs (fraunhofer.de)”.

-

Average consumption of HGVs >25T “climate balance, costs and the different potential fuel and engine types for cars and HGVs S22 2.2.4“. “Climate balance, costs and the different potential fuel and engine types for cars and HGVs“ (fraunhofer.de)”.

Up to 15% could be saved per year and HGV in fuel costs. Currently, MEBREX GmbH is unaware of any development, nether for the HGV engine nor for the chassis, that could reached this goal.

We believe that this saving is possible, even if not in all cases, for a large number of HGVs!

MEC 1.4 - What is it, how does it work and what are the benefits?

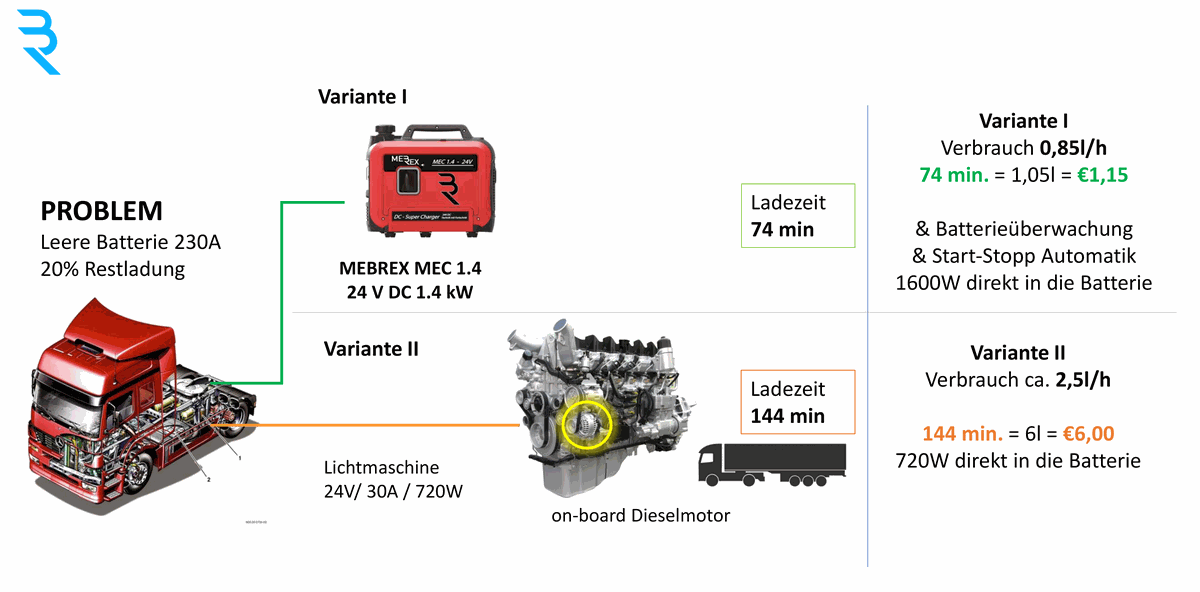

The MEC 1.4 (Fig. 5) is a generator with fast charging function! Fast charging because the generated current is delivered as direct current directly into the battery and thus a battery can be charged twice as fast as the truck engine with its built-in alternator allows at idle. Fig. 6 shows the differences to possible scenarios and their costs of battery charging.

Fig.5

Fig. 6

Service costs:

Due to the possible savings during idle time (as illustrated in Fig. 2), the HGV service interval is increased. Therefore, over a period of many years, one or two service intervals can be saved. These costs are, however, difficult to illustrate owing to manufacturers’ varying interval specifications.

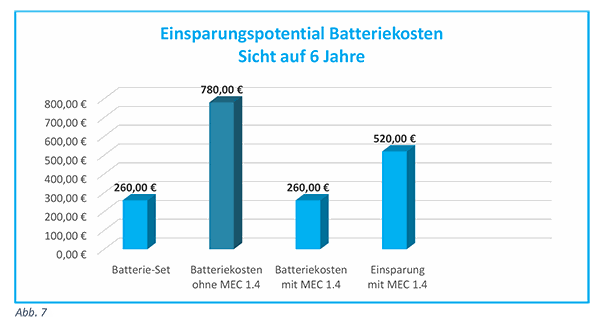

Battery replacement:

Vehicles with higher idle consumption require a battery replacement every two years. Using the MEC 1.4 can extend this time period up to 6 years, as illustrated in the diagram (Fig. 7).

To install this Web App in your iPhone/iPad press ![]() and then Add to Home Screen.

and then Add to Home Screen.